Safety pins are such tiny, everyday objects that most of us never think twice about their little details — especially that tiny hole you can spot on some designs. It’s easy to assume it’s purely decorative, but the hole often has practical, historical, and engineering reasons behind it. Below are multiple perspectives on what that tiny hole is for, why it exists, and the surprising ways that small detail matters.

1. The Hole Is Part of the Spring Mechanism — It Helps Maintain Tension and Reliability

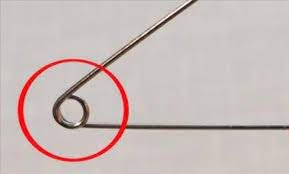

At the most practical level, the tiny hole you sometimes see in a safety pin’s body or clasp isn’t decoration — it’s part of the pin’s mechanical logic. A traditional safety pin is essentially a single length of wire bent into a springy shape: a sharp point at one end, a coiled “spring” in the middle, and a protective clasp at the other. The hole (or small slot) near the clasp or in the folded metal helps control how the wire seats against itself when the pin is snapped closed. By allowing a tiny clearance or by giving a precise spot for the wire end to rest, the hole contributes to predictable spring tension and a reliable snap-back action. Without that engineered relief point, the pin might stick, wobble, or fail to remain securely closed over repeated use. In short, the hole is a small but deliberate feature that helps the safety pin perform its primary function safely and consistently.

2. Manufacturing and Assembly: The Hole Can Be a Production Necessity

If you look at how safety pins are made — a continuous wire is cut, bent, coiled, and shaped — you’ll see why tiny holes or slots sometimes appear. During stamping, coiling, and assembly, small apertures can serve as alignment points, drainage points during plating, or areas that reduce stress concentration where bends are tight. In mass production, giving the metal a tiny hole or notch where it folds can make the spring action more uniform from part to part. It also makes it easier for automated fixtures to position the pin for the final crimping of the clasp. So while the hole may look like a trivial cosmetic detail, it can be a clever manufacturing choice that reduces waste, yields more consistent performance, and speeds automated assembly lines.

3. A Safety and Durability Feature — Reducing Metal Fatigue and Local Stress

Anytime you bend metal, you concentrate stress at the bend. Over repeated opening/closing cycles, that area is where fatigue can start a crack. The tiny hole or slot can act to redistribute or relieve stress slightly, preventing tiny micro-cracks from starting exactly at a single sharp corner. In effect, that small cutout changes the geometry enough to make the metal flex more predictably and survive more cycles. For a humble object like a safety pin — which may be opened and closed many times, sometimes under load — improving fatigue life is important. Designers of small hardware use tiny geometry tweaks like holes, radii, and slots to make inexpensive metal parts last longer and fail less catastrophically. In a safety device, durability equals safety; the hole contributes quietly to both.

4. Helps the Clasp Capture the Point Securely — A Mechanical Seat for the Tip

Beyond spring action and manufacturing, the hole can play a literal seating role. The tip of the pin needs to sit inside the clasp cleanly so that it won’t slip out during use. In some safety-pin designs, a tiny aperture or notch in the clasp body acts as an entry or “eye” that guides and retains the sharp point when the pin is closed. That seating improves both the perceived and real security of the closure: the pin is less likely to release from vibration or a tug. On many higher-quality pins you can see how the tip nests and how the small feature helps it stay put. It’s a tiny alignment and retention aid — low drama, high function.

5. Prevents Corrosion or Trapping of Plating Liquids During Finishing

It may sound odd, but small holes and slots often serve finishing and longevity functions. After manufacturing, many safety pins are plated (nickel, brass, etc.) to resist rust and look attractive. Small cavities or perforations allow plating solutions to flow through and drain, preventing trapped chemicals that could cause uneven finish or hidden corrosion. Drainage holes also allow solvents to escape and speed drying. In some cheap stamped pins, the absence of such detailing leads to trapped moisture and reduced lifetime. So that tiny hole can be a subtle quality marker: a sign that the designer considered finishing and corrosion control, and not just raw shape. Good design often shows in these micro-details.

6. A Nod to the Original Safety Pin Patent and Historical Design Choices

The safety pin we know today traces back to 1849 when Walter Hunt patented it in the United States. His invention was designed as a practical solution for fastening cloth without risking repeated pricks to the user’s skin. When you look at Hunt’s original sketches, you’ll notice the emphasis on spring action, the clasp, and the way the point had to be shielded. Over time, as different manufacturers replicated and refined his design, small tweaks emerged — including the appearance of holes or notches in the clasp. These weren’t arbitrary; they reflected early attempts to balance simplicity of manufacture with long-lasting reliability. In the industrial age, little details like a hole meant less breakage, easier plating, or even simpler molding in certain clasp styles. In that sense, the hole is a fossilized reminder of history: it reflects decades of iterative design thinking since the very birth of the modern safety pin. People often underestimate how even the smallest detail in a long-lived product has roots stretching back more than a century. That hole, in short, isn’t just functional — it’s historical.

7. Enhancing Child Safety — Reducing Sharpness Risks in Baby Garments

One of the most common uses of safety pins has always been in securing baby clothes, diapers, and small garments. Parents needed a tool that would hold fabric together firmly but not easily pop open and injure the child. The clasp, along with any structural holes in it, made this possible. The hole provides a recess where the point can tuck in more securely, preventing accidental pricks. This is crucial for tiny, restless babies who wiggle constantly. Some pin designs even use the hole to anchor a protective cap or decorative cover — further hiding the sharp end. When viewed through this lens, the tiny hole becomes part of a larger mission: ensuring safety for vulnerable users. Without these small innovations, the safety pin might never have earned its place in nurseries worldwide. Parents trust safety pins because details like that hole minimize accidents.

8. Functional Versatility — Letting Safety Pins Double as Sewing Aids

If you’ve ever tried to thread elastic through a waistband or pull a drawstring back into a hoodie, chances are you used a safety pin. In many of these tasks, the tiny hole or notch can serve as an attachment point — you can tie thread, slip in elastic, or hook on small objects while guiding them through fabric. It effectively makes the safety pin a multi-tool for sewing and household repairs. Historically, this functional versatility is part of why safety pins have lasted in popularity. They’re not only for fastening fabric — they also help with threading, pulling, and holding things in place temporarily. The hole may not always be noticed, but crafters often rely on it instinctively: slipping a thin cord into the hole, securing it, and using the pin as a guide. This transforms a one-trick fastener into a helper for multiple DIY and crafting hacks. The small detail of the hole is what expands its range of utility beyond its obvious purpose.

9. A Symbol in Fashion and Subcultures — Where Even the Hole Matters

From punk rockers of the 1970s who wore safety pins as jewelry to modern DIY designers who use them as edgy adornments, the safety pin has long been more than a fastening device. In fashion, every detail matters — including the small hole. Some fashion-oriented safety pins are deliberately manufactured with larger or more visible holes so that charms, beads, or chains can be attached. Others use the hole as part of a design motif, turning utility into decoration. The punk movement, for example, thrived on transforming ordinary, utilitarian items into bold style statements. That small hole became a perfect anchor point for customization — attaching fabric scraps, dangling accessories, or creating clustered pin designs. Without that subtle feature, the safety pin would have been far less versatile as a wearable symbol. In this way, the hole isn’t just engineering — it’s part of cultural history, allowing the safety pin to leap from sewing kit to stage costume.

10. A Quality Indicator — Spotting Strong vs. Weak Safety Pins

Finally, let’s talk about quality. Not all safety pins are made equal. Cheap ones bend easily, snap under pressure, or corrode quickly. Interestingly, the presence, size, and placement of a tiny hole or notch in the clasp can sometimes signal a better-made pin. Why? Because manufacturers who add this detail are typically accounting for stress relief, better plating, or secure tip seating. If you pick up two safety pins side by side — one with a thoughtfully engineered clasp and hole, and another with a flimsy closed clasp — you’ll likely notice the difference in performance. The better pin closes more smoothly, stays locked under tension, and survives multiple uses without warping. In practical terms, that small feature is a subtle but telling marker of craftsmanship. If you care about safety and reliability, especially for uses like fastening fabric close to skin, knowing how to “read” that little hole is a small consumer tip that pays off.

11. The Role of the Hole in Reducing Metal Fatigue

When a safety pin is repeatedly opened and closed, the thin wire undergoes stress. Over time, this constant flexing can weaken the metal and lead to breakage. Engineers who studied small household items like safety pins understood that concentrated stress points were the main culprits in causing metal fatigue. By adding a tiny hole in the clasp, they allowed the pin’s point to sit more comfortably, distributing stress more evenly across the wire and clasp. This reduces the chances of bending or cracking at one point. Imagine the difference between bending a straight paperclip at one sharp crease versus looping it around a curve — the latter distributes the pressure better. The hole works similarly: it ensures the clasp is not bearing all the load directly on its surface, thereby extending the life of the safety pin. This is one reason why older generations could reuse a single pin for months, even years, without it failing. The hole may seem minor, but in truth, it plays a big part in durability.

12. Safety Pins in Emergency Repairs — Hole as a Stabilizing Element

Everyone has, at some point, relied on a safety pin to solve a fashion emergency. Whether it’s a broken zipper before a meeting, a missing shirt button, or a torn hem, safety pins step in as lifesavers. The small hole in the clasp often provides additional stability in these cases. For instance, when you pin together thicker fabric or secure something temporarily, the hole acts almost like a small anchor point, giving the clasp a more secure closure so the pin doesn’t slip out. Without such stability, the pin would be far more likely to pop open under the strain of thicker or layered material. In emergency scenarios, reliability matters — nobody wants a pin springing open in public. That little hole, though barely noticeable, ensures that the point stays snugly inside and doesn’t slide out, no matter how much movement or tugging the fabric endures. It’s precisely this quiet reliability that makes people instinctively keep safety pins in handbags, cars, or travel kits.

13. Psychological Comfort — Why Small Features Inspire Trust

Interestingly, the hole in a safety pin also plays into the psychology of trust. Human beings rely not only on actual safety but also on the perception of safety. The tiny hole adds to that perception because it visually reinforces the sense that the pin has been carefully engineered to prevent accidents. A user looks at it and feels reassured: “This pin won’t easily slip out.” Over decades, such design elements become embedded in cultural consciousness. Parents trust safety pins because they appear more secure than plain pins. Designers know that even if a hole doesn’t add much to strength in a particular model, it increases consumer confidence. This is a fascinating example of how human psychology interacts with small design details. In essence, people want to see evidence of safety mechanisms, no matter how subtle. The hole in the clasp silently communicates: “We’ve thought of your safety.” That sense of trust is why safety pins have remained a household staple for generations, rather than being replaced by alternatives.

14. The Hole’s Role in Reducing Manufacturing Waste

From an industrial perspective, efficiency is everything. When producing millions of safety pins, even the smallest design tweaks can save material or simplify processes. The tiny hole in some safety pin clasps is not only functional but also economical. By removing a fraction of metal where it isn’t needed, manufacturers save on raw material costs across massive production runs. While the savings per pin are minuscule, multiplied by millions, they add up significantly. Additionally, the hole can simplify plating or coating processes by allowing chemicals to flow more evenly around the clasp during electroplating. This ensures the safety pin is uniformly protected from rust and corrosion. Without this, some areas might be inconsistently coated, leading to weaker products. Thus, the hole reflects a marriage of cost-efficiency and functionality. It shows how industrial design balances user needs with factory realities — a perfect reminder that every tiny detail in mass-produced objects has economic reasoning behind it.

15. Symbolic Interpretations — The Hole as a Metaphor of Openness

Beyond engineering and practicality, humans often attach symbolic meaning to everyday objects. In art, literature, and even cultural traditions, the safety pin has been used as a metaphor for connection, resilience, and hidden strength. Interestingly, the small hole itself can also take on symbolic interpretations. Some artists see it as a representation of openness — a reminder that strength doesn’t always come from being solid but sometimes from leaving space. Fashion designers who repurpose safety pins into jewelry often highlight the clasp and hole, turning what seems like an insignificant void into a focal design element. It becomes not just a functional recess but an aesthetic or symbolic statement. This is why you’ll find the safety pin in everything from protest art to poetry. The hole reminds us that sometimes, the smallest spaces are what make a structure safe, useful, and meaningful. It transforms an everyday fastener into a tiny object of philosophy.

Conclusion

When we look at a safety pin, it’s easy to dismiss it as just another tiny household object — simple, cheap, and almost invisible in our daily lives. Yet, as we’ve explored, even the smallest details of its design carry profound thought, purpose, and functionality. The tiny hole in the clasp isn’t there by accident or as a decorative afterthought; it exists because engineers, manufacturers, and users demanded safety, durability, and reliability in one compact tool. From reducing metal fatigue to stabilizing fabrics, from inspiring psychological trust to serving as an anchor in emergency fixes, this hole transforms an ordinary piece of bent wire into something extraordinary.

What makes the safety pin fascinating is not just its utility, but also the way it mirrors life itself. Sometimes, the smallest spaces, the tiniest gaps, or the most overlooked details can end up making the biggest difference. The hole represents thoughtfulness in design — proof that even a “minor” feature can ensure both safety and trust across generations. It also reminds us of a deeper truth: good design is invisible, working silently in the background while we go about our lives.

So, the next time you pick up a safety pin, pause for a second. Notice that little hole. Behind it lies a story of engineering brilliance, cultural symbolism, psychological reassurance, and manufacturing ingenuity. It’s a perfect example of how even the humblest objects in our lives are shaped by creativity, precision, and purpose. And maybe that’s the greatest lesson of all: nothing is ever too small to matter.